Support (Coating Problems).

Side Vented Coating Machines

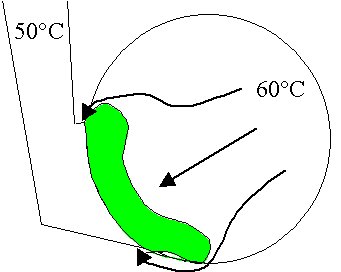

One of the main reasons for side vented coating machines giving problems is connected to the exhaust plenum seals. Often overlooked the exhaust plenum seals can mislead the operator and give problems of over wetting or long process times. The problem is air will take the easiest path and if seals are damaged or worn the air can skip around the tablet bed reducing the drying efficiency. The reduction in drying air will extend the process time or can give an inaccurate indication of tablet bed temperature. Indicating the exhaust air at a higher temperature than the actual tablet bed giving the possibility of over wetting. All air within the process path should pass via the tablet bed heating and efficiently drying the tablets in process, any air missing the tablet bed is effectively a loss. Additionally if air is allowed to avoid the tablet bed by leaking in to the plenum due to faulty seals the air path is disturbed and can give rise to the spray path being erratic allowing the spray pattern to spray parts of the machine it should not this can also increase spray drying and additional product loss. Plenum seals are the only regular maintenance within a machine and should be checked at least once a year. Often the access to the seal is in a service area and the operator is unaware of the need to check or the impact on process.